2025 Publications

Selective growth of ZnO micro- and nano-structures on fs-laser processed metallic Zn substrates for large area applications

R. Ariza, A. Urbieta, A. Ferreiro, M.E. Rabanal, P. Fernández, J. Solis

Journal of Alloys and Compounds, Volume 1010, 5 January 2025, 177797

Journal of Alloys and Compounds, Volume 1010, 5 January 2025, 177797

Abstract

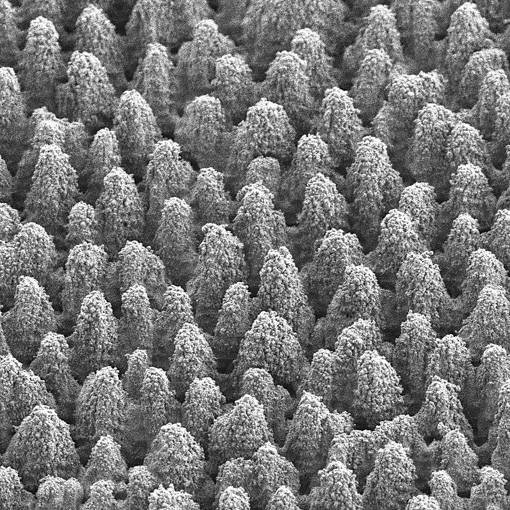

The synthesis of large area micro- and nano-structured ZnO surfaces has been successfully achieved through a two-step process. It involves the irradiation of Zn metal sheets with femtosecond laser pulses (350 fs at 1030 nm) at high repetition rates (100–500 kHz), and fast scanning speeds (cm/s). Subsequently, the irradiated sheets are thermally treated in an Argon flux at 380 °C, a temperature significantly lower than that typically required for growing micro- and nanostructures in ZnO. Fs-laser irradiation promotes the initial development of topography and the localized oxidation of the metal. This enables the further growth of micro- and nanostructures at preferential sites with good crystalline quality and luminescent properties. Analysis of the material at different processing steps shows that the initial laser-induced oxidation is crucial in defining ZnO growth mechanisms upon thermal treatment, and determining the final properties. We have tested the potential use of these structures as reusable photocalyst. The ease of catalyst recovery in photocatalysis experiments and the degree of degradation achieved may be considered as key performance indicators. Photocatalytic activity tests performed with a Rhodamine B solution showed degradation values up to 43 % over 90 min. The morphology of the samples remains unaltered after photocatalysis experiments.

Tuning spike-like morphologies in Silicon by sustainable fs-laser processing in air for enhanced light absorption

Gonzalo Gómez Muñoz, Rafael Benítez Fernández, Guillermo Godoy Pérez, Fátima Cabello, Marina García Pardo, Daniel Caudevilla, José Gonzalo, Javier Solís, Mario García Lechuga, Javier Olea, David Pastor, Jan Siegel

Applied Surface Science, 686, art. no. 161967

Applied Surface Science, 686, art. no. 161967

Abstract

The manipulation of the optical properties of plasmonic nanocomposites is of high interest for the development of advanced optical devices with tailored unique properties. Achieving these objectives requires a combination of synthesis techniques and post-fabrication strategies. Here, we combine the use of two well-established physical strategies: MeV ion implantation and femtosecond laser processing. Firstly, we synthesize Au-doped soda lime glass nanocomposite through ion beam implantation (Au2+ at 1.8 MeV) followed by thermal annealing. This synthesis procedure results in a peculiar optical response based on the combination of Au-nanoparticle plasmonic resonance and a Fabry-Perot interference, caused by the deep implantation (centered at 480 nm). Secondly, this dual response is demonstrated to be highly tuneable by non-resonant femtosecond laser irradiation (800-nm wavelength and 130-fs pulse duration). Depending on the laser fluence, three transformation regimes are distinguished: supressing the interferometric response by spallative ablation, inducing vivid blue colors by surface swelling, and producing red-shifted color changes by multi-shot irradiation at low fluences. The proposed method is very versatile, since it is applicable to any dielectric matrix or implanted element. This work paves the way to a new route for the development of scalable and tuneable nanocomposites with several potential applications in optics.